Induction Cap Sealing System

Induction cap sealing system. Cap sealer model MRCS 1000 Multipurpose air-cooled generator - Induction Cap Sealing system. The sealed container moving on conveyor belt are transport through conveyor the container come below the sealing head in the subsequent indexing part and induction head will give appropriate heat as per pre-set temperature and the container will seal the by pre-fitted wad or. With no sealing head fan and no water cooling system the CS Plus200SS offers superior.

Induction Cap Sealing System - YouTube. Induction cap sealing machine is responsible for safeguarding the products enhance the efficiency and self line. Hand Held Induction Sealer.

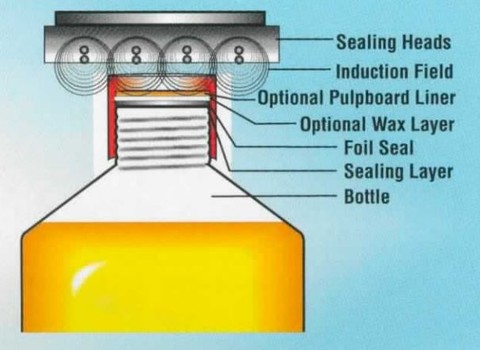

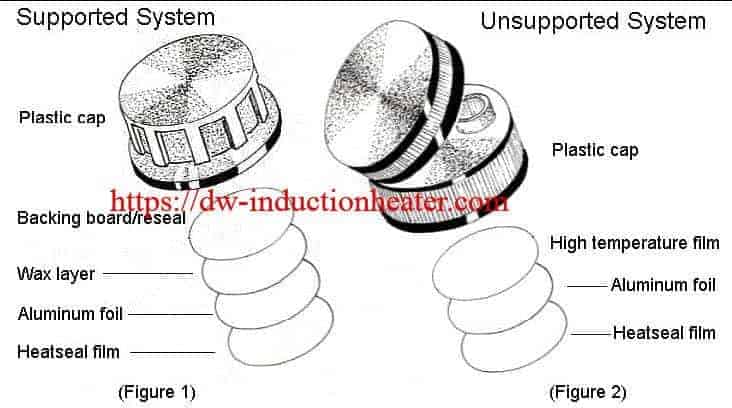

So for cap sealing it involves a non-contact mechanism of applying heat to the inner seal usually aluminum foil since its an electric conductor of. Induction cap sealing is a non-contact method of heating an inner seal to hermetically seal the opening of plastic or glass containers. Induction cap sealing is a very simple and straightforward process that offers many benefits.

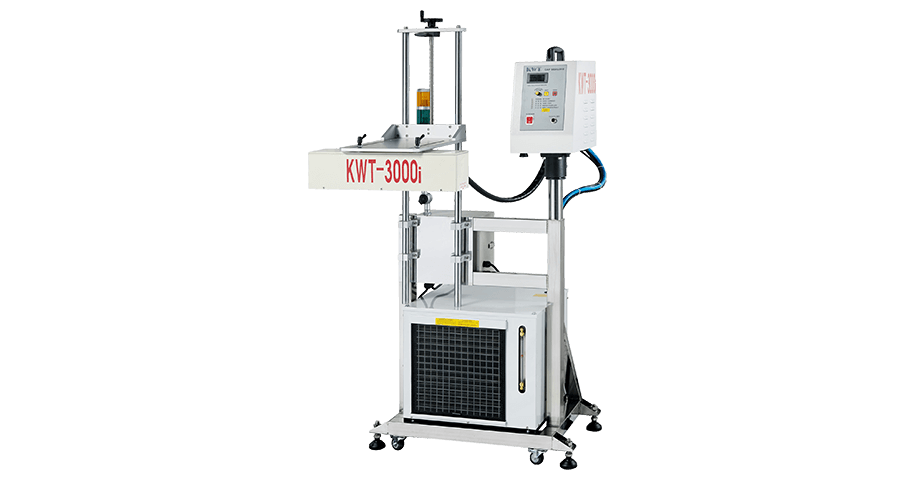

High speed and high quality induction sealing machine. Set stock alerts on changing inventory use BOM tool w auto column mapping and more. For all applications contact Kaps-All for Waterless Induction Cap Sealing Systems.

Three models are available to suit all of your production needs. The Super Seal Jr hand-held induction sealer offers the combination of sealing capability and portability. Induction Cap Sealing Basics.

Super Seal induction sealing technology has sealed over 50 billion containers around the planet. With dinamic sealing the induction coil is centred over the filling line conveyor belt and sealing is carried out on the moving containers. Capped containers pass under an induction cap sealer mounted over a.

The cap and closure machines have a maximum speed of up to 160-200 caps per minute. The IGNITE HH is extremely simple to handle carry and operate and is the perfect answer to your portable induction sealing needs.

With dinamic sealing the induction coil is centred over the filling line conveyor belt and sealing is carried out on the moving containers.

Induction sealers are simple to use and provide an efficient way to seal bottles creating a packaging seal that can not be tampered with whatsoever. With dinamic sealing the induction coil is centred over the filling line conveyor belt and sealing is carried out on the moving containers. Three models are available to suit all of your production needs. Induction Cap Sealing Systems - Cap Sealing Machines. Capped containers pass under an induction cap sealer mounted over a. By eliminating the filters hoses pumps radiators flow switches water and mess these induction cap sealing systems have less chance of part failure and. High speed and high quality induction sealing machine. With no sealing head fan and no water cooling system the CS Plus200SS offers superior. The induction sealing technology is a sector in full expansion where MERO has emerged as a leading company.

Waterless induction cap sealing systems are beneficial in that they are less than 12 the size of water cooled systems. Capped containers pass under an induction cap sealer mounted over a. The cap and closure machines have a maximum speed of up to 160-200 caps per minute. The Enercon Super Seal induction cap sealer is the industry standard for cap sealing. Induction Cap Sealing Basics. Ad Leading manufacturer on Continous Induction Sealer with advanced technology. Induction cap sealing machine is responsible for safeguarding the products enhance the efficiency and self line.

Post a Comment for "Induction Cap Sealing System"